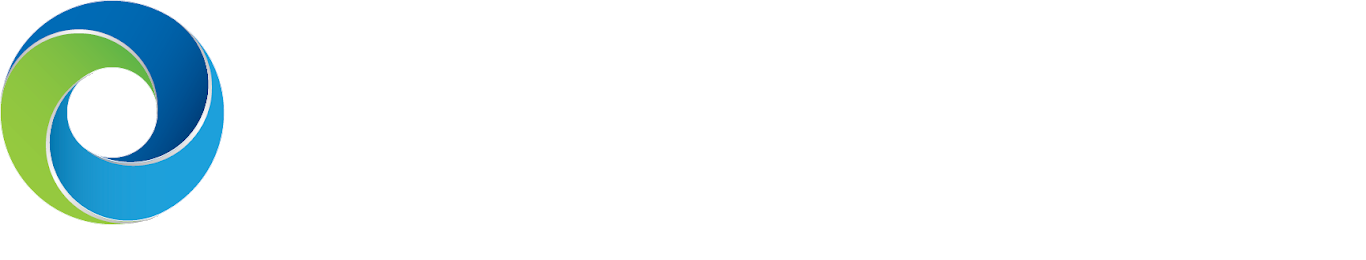

Mi-Glow® 418

Our Solution Results in:

- Reduction of Mi Glow 418 consumption in NDT processes

- Greater sensitivity and brightness of the Mi Glow 800 & Mi Glow 920 results in faster NDT inspections

- Post heat treatment MPI capability (high temperature)

Mi-Glow® 418

Advantages

- Borate free wetting agent with excellent wetting characteristics

- Low foaming – Well controlled water conditioning agents

- Economical - requires 53% less product to achieve desired concentration within a fluorescent MPI system (MG 418 requires 6 g/L compared to our direct competitor of 11.25 g/L)

- Circle Systems unique bonding method offers a very tightly bonded particle which

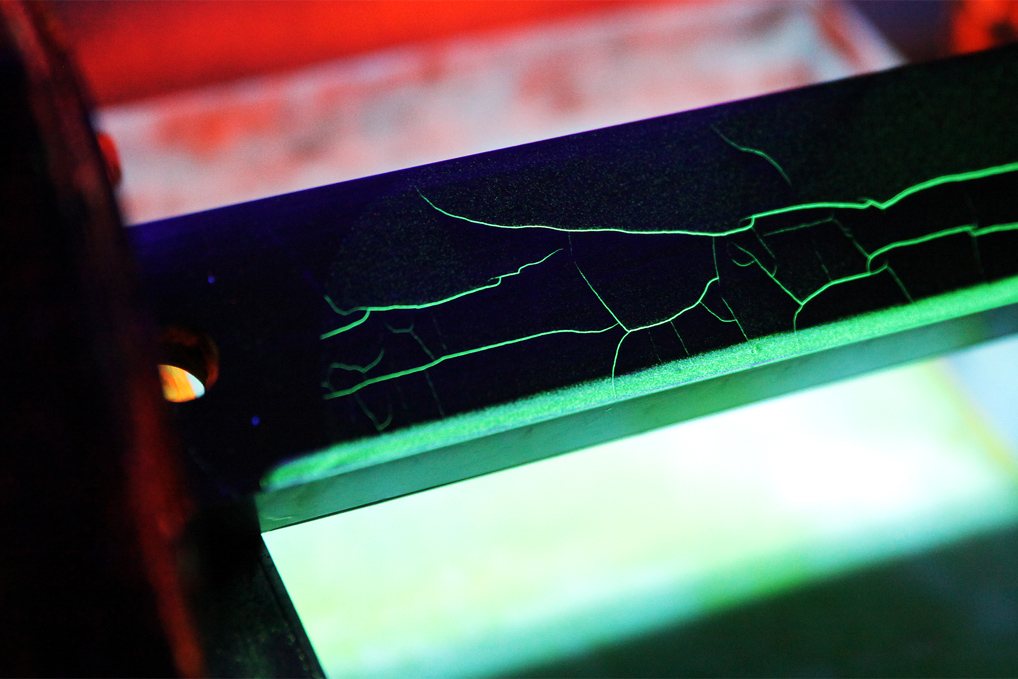

Provides total particle encapsulation, eliminating free unbonded pigment, resulting in a low background, high performing magnetic particle inspection powder

Sensitivity – The superior Mi Glow 800 & Mi Glow 920 particles have larger surface areas which mean smaller sized particles with increased sensitivity and brightness

Ordering and Specifications

Packaging

Item # / Package Size

#3320 – 30 pounds/pail

Technical Specifications

Physical Characteristics

Green powder with a slight detergent odor.

Particle Certification

Certifications are dependent on the lighting conditions used in the inspection area. For the specific inspection conditions described (see Technical Bulletin 284 for detailed description of different inspection conditions), the particles meet or exceed relevant industry specifications including but not limited to:

Darkened Inspection Area – ASTM E 709, ASTM E 1444, AMS 3044, MIL-STD-271, NAVSEA 250-1500-1, NTR-1E

Undarkened Dual Response Inspection Area – ASTM E 709, NAVSEA 250-1500-1

Certification is included with each shipment.

Particle Color: Fluorescent Yellow-Green

Average Particle Size: 7.5 µm

AMS Standard: 3044†

SAE Sensitivity*: 8

Temperature Range: 32-300°F (0-149°C)‡

*Representative of the number of lines shown on a tool steel ring as defined in SAE AS5282.

†When lighting conditions meet those identified in a darkened inspection area as outlined in Technical Bulletin 284.

‡Refer to special instructions in Technical Bulletin 284 when using in temperatures above 120°F.